High pressure hydraulic hoses

-

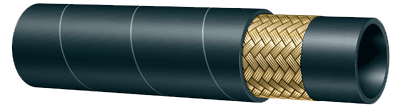

ClassBASIC

ClassBASIC -

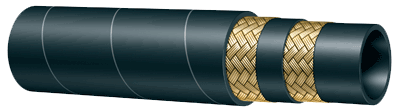

ClassSTANDARD

ClassSTANDARD -

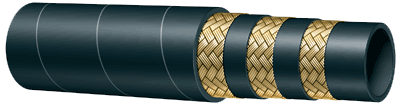

ClassPROFESSIONAL

ClassPROFESSIONAL

High Pressure Hydraulic Hose

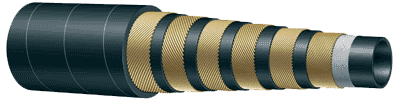

Hydraulic hose or high-pressure hydraulic hose, as it is usually called, is an integral part of a flexible hydraulic line that is used to transfer hydraulic and mineral oil, fuel, gas and emulsions under high pressure. High-pressure hydraulic hose can be found everywhere, where it's impossible to install rigid pipes. It is more often installed in the bending spots, e.g. to transfer energy to lift an earth mover's bucket. High-pressure hoses can transfer both energy and the product, such as drill fluid or slurry that's used in the process of hole boring. Hydraulic hose has several layers: an internal rubber layer, steel or textile reinforcement, and an external rubber layer. In most cases the synthetic rubber compound, such as or similar to NBR (Nitrile Butadiene Rubber) used for external and internal layers.

The Construction of a Hydraulic Hose

Most of the hydraulic hoses are made out of special hermetic internal rubber layer, steel or textile reinforcement and protective external layer. Internal layer of a hydraulic hose is manufactured out of the special rubber compound using method of extrusion. That special rubber compound guarantees high level of durability and resistance to severe compounds that may flow through hydraulic hose. Layer of reinforcement, made out of high-tensile steel or textile wire, placed in the middle. Hydraulic hose is getting reinforced by using special braiding machines. There can be several layers of reinforcement that allows hydraulic hose to withstand very high level of pressure.

Process of manufacturing and assembling of hydraulic hoses

Under process of manufacturing and assembling often understood the process of crimping of a hydraulic hose. There are several stages in this process:

- Taking measurements of hose's external diameter;

- Cutting hydraulic hose;

- Skiving off an external layer of a hose (if necessary);

- Skiving off an Internal layer of a hose (if necessary);

- Inserting, manually or using inserting machine, ferrule and fitting;

- Crimping using the crimping machine;

- Testing assembled hydraulic hose (impulse and burst tests);

- Cleaning hydraulic hose with water or air;

- Installing PVC caps on hose’s ends to prevent contamination.

The types of Hydraulic Hoses

Nowadays hydraulic hose manufacturers produce all sorts of various types of hydraulic hoses with different diameters, different resistance to the working environments and different working pressure that solely depends on the construction of a hose. Today, in general, we can distinguish following types of hydraulic hoses:

-

Single-braid hoses, such as 1SN, 1SC

Single-braid hoses, such as 1SN, 1SC -

Two-braid hoses, such as 2SN, 2SC

Two-braid hoses, such as 2SN, 2SC -

Three-braid hoses, such as 3SK

Three-braid hoses, such as 3SK -

Four-spiral hoses, such as 4SP, 4SH

Four-spiral hoses, such as 4SP, 4SH -

Six-spiral hoses, such as R13, R15

Six-spiral hoses, such as R13, R15

Hydraulic Hose Application

The high-pressure hydraulic hoses are used in most areas of industrial application, where the pneumatic and hydraulic circuits are needed:

-

Construction Machinery

Construction Machinery -

Agricultural Machinery

Agricultural Machinery -

Mining Equipment

Mining Equipment -

Forestry Equipment

Forestry Equipment -

Public Utilities

Public Utilities -

Oil and Gas Industry

Oil and Gas Industry